Efficient LED UV Curing Technology for Coating Industries.

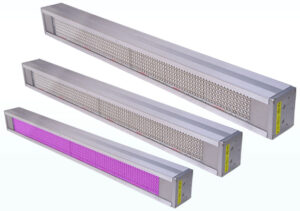

LED UV CURING SYSTEM

EFFICIENT LED UV CURING TECHNOLOGY FOR COATING INDUSTRIES

LED technology has become a real alternative solution in the sphere of light curing. To date, the efficiency of both the individual LED’s and the system as a whole have been increased, resulting in further improved drying quality. Simple integration, dispensing with ozone and mercury and the lack of thermal radiation favor a broad range of applications for this technology in industrial curing.

Whether in the curing of printing inks, adhesives or varnishes on various substrates – LED UV curing is seeing high growth rates in coating industries. However, distribution of the two technologies differs widely in the various segments. Overall, LED systems are most frequently used in inkjet and adhesives applications.

WHAT IS LED UV CURING

LED UV systems are used for materials that contain photo initiators, for example in applications for curing adhesives in bonding or sealing processes or for drying materials such as inks, lacquers, paints, and clear coats. Especially UV light, leads to photo polymerization or radiation curing.

PRODUCT FEATURES

- Easy To Install & Compact Design

- Only 1 LED Cassette required for 4 colour

- Compatible with all Presses

- Life of Diode 25000 working hrs

- Wave length is 365 – 395 nm

- About 80% Power Saving

- Single Touch Operating System

- No Heat Generated such as Conventional UV

AREA OF APPLICATION

- Printing Industry

- Rubber Industry

- Automobile Industry

- Wood & Floor Paint Industry

- Fungi & Sterilization Treatment

ADVANTAGES OF LED

- It is Environmental Friendly

- It gives Consistent Print Quality

- It is compatible with Special Media

- It greatly reduced Power Consumption

- No Ozone Smell

- No Infrared Light

WHY LED?

General Features

- Basics of Systems

- Power Consumption

- SASG LED Life Time

- Temperature during operation

- Type of Source

- Environmental/health issues

- Maintenance Required

- Quality of Printing

LED UV

- Silicon Emitting Diode LED

- Low normally quantified hundreds of Watts/hr

- More than 25000, working hrs hours.It depends on the condition of use and the environment.

- 600 max. measured in lamp emitting window

- Monochromatic source for UV-a rays only

- No Mercury and other dangerous substances environment.

- No Mercury and other dangerous substances environment.

- Printing quality more constant

Mercury UV

- Fragile cylindrical quartz bulbs

- High normally quantified thousand of Watts/hr.

- Varying from 500 to 2,000 working No technical maintenance.

- Greater than 13500C on lamp window.The bulb can reach 9000C after a few minutes of operating.

- Rays emitted UV-A+UV-B+UV-c

- Contains mercury and metal halite potentially dangerous for the health.

- Frequent ordinary maintenance glass and production downtime

- Electromagnetic system containing transformers, Chokes, capacitors and igniter.

Advantages of LED

- High resistance to vibration and shock

- Power consumption is 70% less:thus investment cost is recovers by the user in a short time

- No UV emitter to replace.

- LED is instant ON/OFF there for save ample energy over mercury UV System

- Improved safety for the operation.It does not emit dangerous UV-C radiation

- It is not necessary to dispose emitter as special waste.

- Almost zero maintenance cost

- LED lamps is more compact and reliable over time/speed.