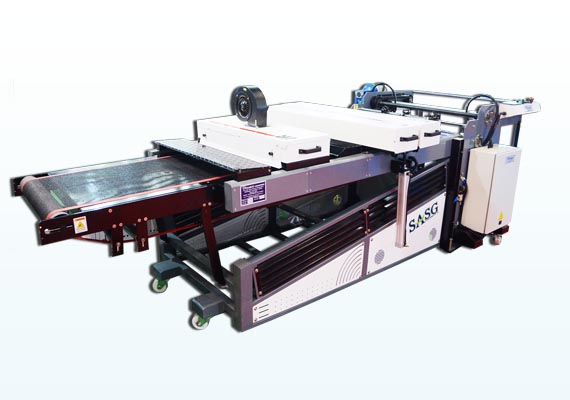

UV Conveyor System is a high speed UV curing machine.

UV Curing System is a high speed UV curing machine. It is a chemical reaction when UV varnish or ink is applied to object and when it passes through UV light it gets cured instantly.

It is basically a Polymerization of UV Lacquer on object through UV Light. UV Curing System is useful for hardening of coating by ultraviolet radiation.

UV Curing System is available in different sizes and power.

SASG UV Solutions offering following UV Curing Machines:

- Advanced UV Curing Machine

- UV Interdecks

- 3D UV Curing System

- UV Curing Lamps

- Hot Air Dryer

FEATURES OF UV CURING SYSTEM

- Easy to operate

- Longer Lamp Life

- Automatic UV hood raise for fire safety

- EPS Power Pack (available on requirement)

- Lower Electricity Consumption

- Suction Hold Down for uniform Paper Travel/li>

- High quality Transformers for minimised Energy loss

- High speed Stackers for Thin paper Stacking

- Adjustable Height for multiple use for offset presses

- Heavy duty cast Iron Blower for maximum heat extraction and noise-free operation

ADVANTAGES OF UV CURING SYSTEM

- Improve parts quality Printing Industry

- Increase productivity

- Lower consumption cost

- Lower operating cost

- Produce eco-friendly

UV CONVEYOR – BEST FOR SCREEN PRINTING MACHINE & PCB

- Easy to Install & require less maintenance

- World class UV Technology

- Quickly press integrated

- Require less floor area

- Easy to operate “zero make ready time”

- Fast Curing & useful for high output production

TABLE TOP- MINI UV CURING SYSTEM

Table top machines are manufacturing in strict technical specifications and offer compact design for easy mobility and installation. These are also fitted with a heat resistant mesh conveyor belt to reduce the heat transfer.