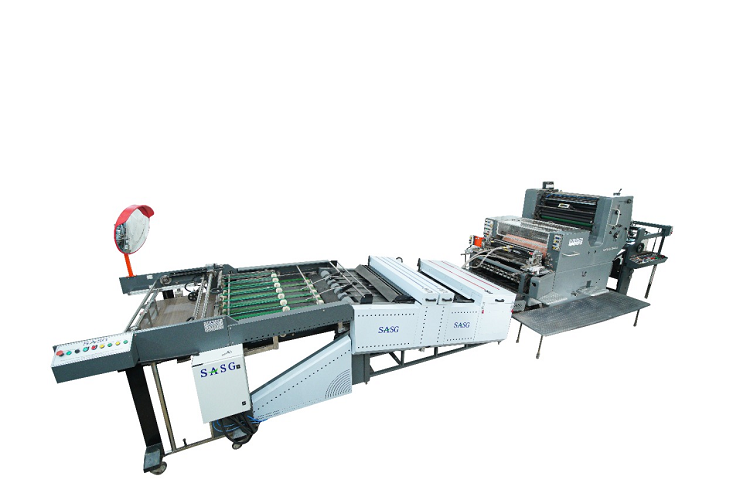

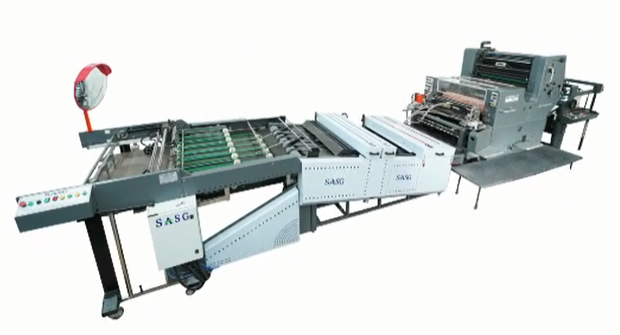

SASG Drip master

SASG Drip master ( A dedicate machine for all coating such as spot uv,drip off & hybrid , uv flood coating , window coating , aquas coating , HSL coating valvet coating and any other kind water base and uv coatings )

REFURBISHMENT IN HEIDELBERG MACHINE CONVERT INTO DRIP MASTER

- REFURBISHING THE ROLLER OF 1ST UNIT IN COMBI ROLLERS

- REMOVE THE INK ROLLERS OF SECOND UNIT

- CONVERT THE EXISTING BLANKET CHASIS MAKE COMPATIBLE FOR BLANKET AND POLYMER PLATE

- CUTTING THE BODY OF SECOND UNIT

- REWIRING OF THE EXISINTING PANEL OF MACHINE

- CONVERT THE EXISTING PANEL INTO THE RETAL PANEL

- ADD THE DRIVE WITH MASTER DRIVE MOTOR OF MACHINE FOR SMOOTH SYNCHRONIZING & POWER SAVING

- CHANGE THE MACHINE MANUAL & PUSH BUTTON SYNCHRONIZED WITH HMI & PLC DELTA MAKE

- REPAINT THE EXISITNG MACHINE

- CLAENING & REFURBISHING TEETH OF THE GRIPPERS-REFURBISHMENT UV COMPITABLE

- IF MACHINE DON’T HAVE THE VACUUM PUMP PROVIDING THE SAME

- SNCHRONIZED THE ENTIRE MACHINE WITH EACH OTHER IN ASPECTS OF JOB APPLICATIONS & PRESS SPEED VARIATIONS

Applications

- Drip-Off UV /Full UV/ Hybrid

- UV Flood Coating

- Window Coating

- Aquas Coating

- HSLCoating

- Velvete Coating

- Any other kind of water based & UV Coating

FEATURES

- Zero Make ready time

- Maintenance free

- Speed of 10000SPH

- HMI Interface

- Less Change -Over Time

- Safety /Security on Hibernation

- Easy to operate